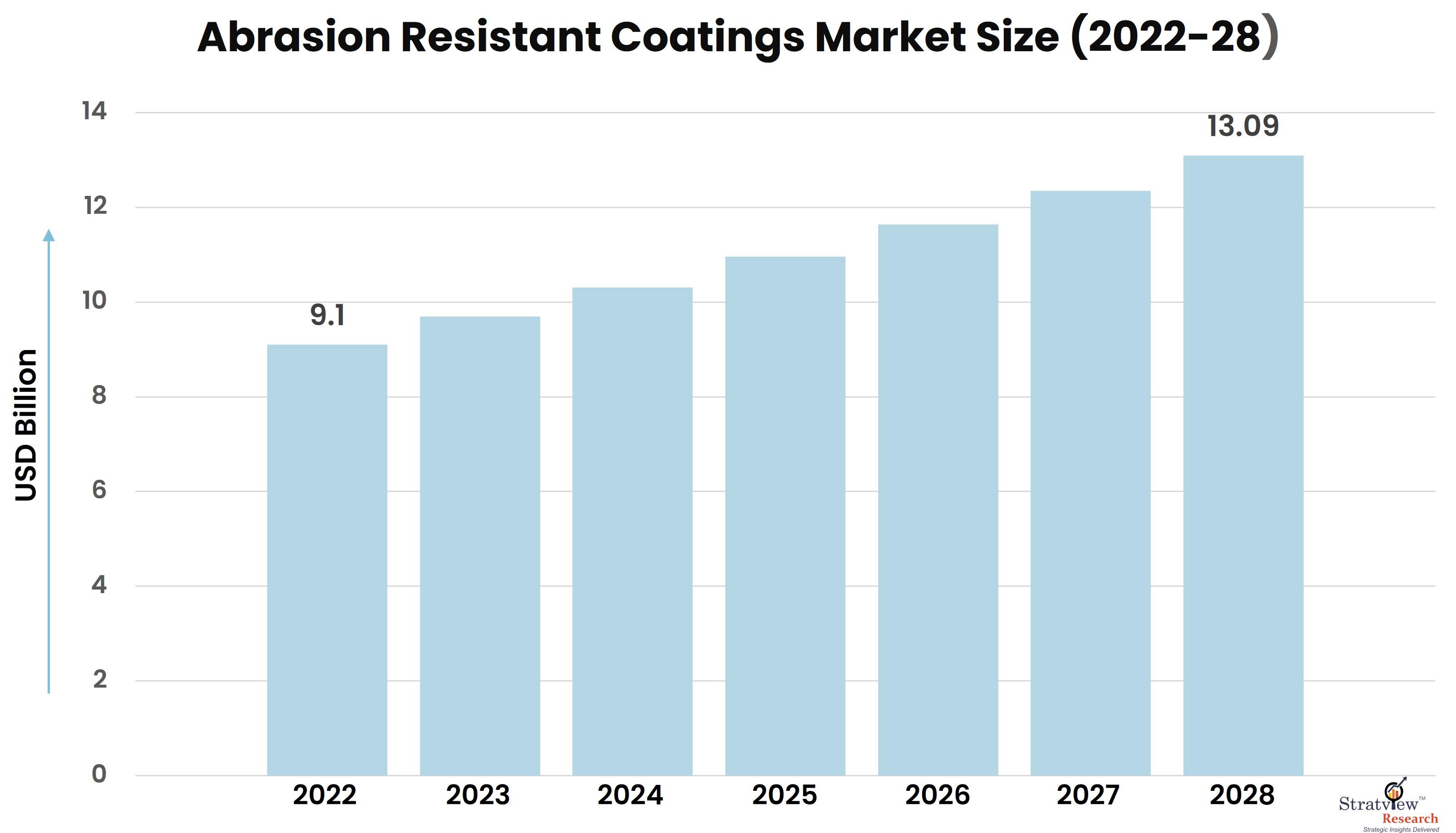

According to Stratview Research, the abrasion resistant coatings market was estimated at USD 9.1 billion in 2022 and is likely to grow at a CAGR of 6.2% during 2023-2028 to reach USD 13.09 billion in 2028.

In a world where surfaces are constantly subjected to the rigors of daily use, abrasion resistant coatings emerge as indispensable defenders against wear and tear. From industrial machinery to automotive components and infrastructure, these coatings play a pivotal role in prolonging the lifespan and preserving the integrity of surfaces exposed to harsh environments. In this article, we delve into the realm of abrasion resistant coatings, providing insights into their significance, applications, and the technologies driving their effectiveness.

Understanding Abrasion Resistant Coatings: Abrasion resistant coatings are specially formulated protective layers applied to surfaces to mitigate the effects of mechanical wear, friction, and erosion. These coatings act as a barrier, shielding surfaces from damage caused by abrasive materials, impact, and environmental factors. By enhancing surface hardness, toughness, and resistance to scratching and abrasion, these coatings offer invaluable protection across a wide range of industries, from manufacturing and construction to aerospace and automotive.

The Significance of Surface Protection: Surface degradation due to wear and tear poses significant challenges across various industries, leading to increased maintenance costs, downtime, and reduced operational efficiency. Abrasion resistant coatings provide a cost-effective solution to these challenges by extending the lifespan of critical components, reducing the frequency of repairs and replacements, and improving overall performance and reliability. Additionally, these coatings contribute to enhanced safety and environmental sustainability by minimizing the risk of equipment failure and reducing waste and energy consumption associated with maintenance activities.

Applications Across Industries: Abrasion resistant coatings find diverse applications in numerous industries where surfaces are exposed to abrasive or corrosive conditions. In the automotive sector, these coatings are applied to vehicle exteriors, wheels, and underbody components to protect against stone chips, scratches, and road debris. In manufacturing and heavy machinery, they safeguard equipment surfaces from abrasion, corrosion, and chemical exposure, ensuring optimal performance and longevity. Similarly, in the aerospace and marine sectors, these coatings are utilized to protect aircraft, ships, and offshore structures from wear and environmental degradation, enhancing safety and durability in demanding operating environments.

Technological Innovations: The effectiveness of abrasion resistant coatings is continually being enhanced through technological innovations and advancements in coating formulations and application techniques. Manufacturers are developing high-performance coatings with improved adhesion, flexibility, and resistance to impact and chemical degradation. Nanotechnology is also playing a significant role in the development of nano-enhanced coatings with superior abrasion resistance and self-healing properties. Furthermore, the integration of smart coatings with sensing and monitoring capabilities enables real-time assessment of surface condition and performance, facilitating proactive maintenance and asset management.

Future Outlook: As industries continue to prioritize efficiency, reliability, and sustainability, the demand for abrasion resistant coatings is expected to grow. Technological advancements, coupled with increasing regulatory scrutiny and emphasis on asset optimization, will continue to drive innovation and market expansion. Additionally, the emergence of new applications, such as renewable energy infrastructure, electronic devices, and medical implants, presents opportunities for further growth and diversification in the abrasion resistant coatings market. By leveraging insights from research and development, collaborating with industry partners, and embracing emerging technologies, stakeholders can unlock the full potential of abrasion resistant coatings in defending against wear and tear and ensuring the longevity of critical assets and infrastructure.

Conclusion: In conclusion, abrasion resistant coatings play a vital role in defending against the detrimental effects of wear and tear on surfaces in various industries. By providing effective protection against abrasion, impact, and environmental degradation, these coatings contribute to enhanced durability, reliability, and safety of critical components and infrastructure. As technology continues to advance and market demand evolves, the abrasion resistant coatings market is poised for continued growth and innovation. By staying abreast of industry trends and insights, stakeholders can harness the full potential of abrasion resistant coatings to address surface protection challenges and drive sustainable value across diverse applications.