Introduction

In the dynamic landscape of manufacturing, achieving success hinges on the ability to optimize production lines effectively. This article delves into the intricacies of production line optimization, exploring strategies to fine-tune operations, enhance efficiency, and drive overall success.

Outline

- Understanding Production Line Optimization

- Significance of Efficient Production Lines

- Strategies for Fine-Tuning Production Lines

- Overcoming Implementation Challenges

- Real-world Applications and Case Studies

- Future Trends in Production Line Optimization

- Conclusion

- FAQs (Frequently Asked Questions)

Background

Production line optimization is the process of refining manufacturing operations to improve efficiency, reduce waste, and maximize productivity. It involves analyzing every aspect of production, from equipment utilization to workflow design, to achieve optimal performance.

Understanding Production Line Optimization

At its core, production line optimization focuses on streamlining processes, eliminating bottlenecks, and enhancing throughput. By fine-tuning production lines, manufacturers can minimize downtime, reduce costs, and meet customer demands more effectively.

Significance of Efficient Production Lines

Efficient production lines play a crucial role in driving profitability, competitiveness, and customer satisfaction. They enable companies to respond swiftly to market changes, produce high-quality products at lower costs, and maintain a competitive edge in the industry.

Strategies for Fine-Tuning Production Lines

Several strategies can be employed to fine-tune production lines, including:

- Lean manufacturing principles to eliminate waste and improve flow

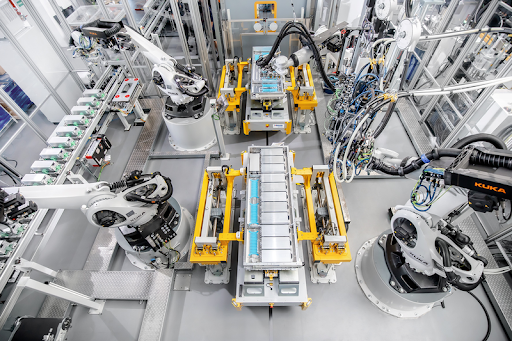

- Implementing automation and robotics to enhance productivity

- Adopting predictive maintenance to minimize downtime

- Utilizing data analytics for real-time monitoring and decision-making

- Continuous improvement initiatives to drive ongoing optimization efforts

Overcoming Implementation Challenges

While production line optimization offers substantial benefits, implementing these strategies may encounter challenges such as resistance to change, a lack of resources, and integration issues. Overcoming these challenges requires effective change management and a commitment to continuous improvement.

Real-world Applications and Case Studies

Real-world applications and case studies provide valuable insights into the benefits and challenges of production line optimization. They showcase how companies across various industries have successfully fine-tuned their production lines to achieve remarkable results in efficiency and profitability.

Future Trends in Production Line Optimization

The future of production line optimization is shaped by emerging technologies like AI, IoT, and advanced analytics. These technologies enable predictive maintenance, remote monitoring, and adaptive control, paving the way for smarter, more agile manufacturing operations.

Conclusion

Fine-tuning production lines is an ongoing process that requires a holistic approach, incorporating technology, process optimization, and employee engagement. By embracing the art of production line optimization, companies can unlock new levels of success and resilience in an ever-evolving market.

FAQs (Frequently Asked Questions)

-

What is production line optimization? Production line optimization involves refining manufacturing processes to improve efficiency, reduce waste, and maximize productivity.

-

Why are efficient production lines important? Efficient production lines drive profitability, competitiveness, and customer satisfaction by enabling companies to respond swiftly to market changes and produce high-quality products at lower costs.

-

What strategies can be used for fine-tuning production lines? Strategies include lean manufacturing principles, automation, predictive maintenance, data analytics, and continuous improvement initiatives.

-

What challenges are associated with implementing production line optimization? Challenges may include resistance to change, lack of resources, and integration issues, which require effective change management and commitment to continuous improvement.

-

What are the future trends in production line optimization? The future is shaped by emerging technologies like AI, IoT, and advanced analytics, enabling smarter, more agile manufacturing operations through predictive maintenance, remote monitoring, and adaptive control.