Stainless steel stands out as a popular material for CNC machining due to its exceptional combination of properties. Here's a detailed breakdown of the key advantages it offers:

Excellent Strength and Durability

l High Tensile Strength: Compared to mild steel, brass, and many aluminum alloys, stainless steel has higher tensile strength. This results in a material that can withstand high forces and stresses without deforming or breaking. This makes it ideal for components that require strength and durability, such as machine parts, structural elements, and aerospace components.

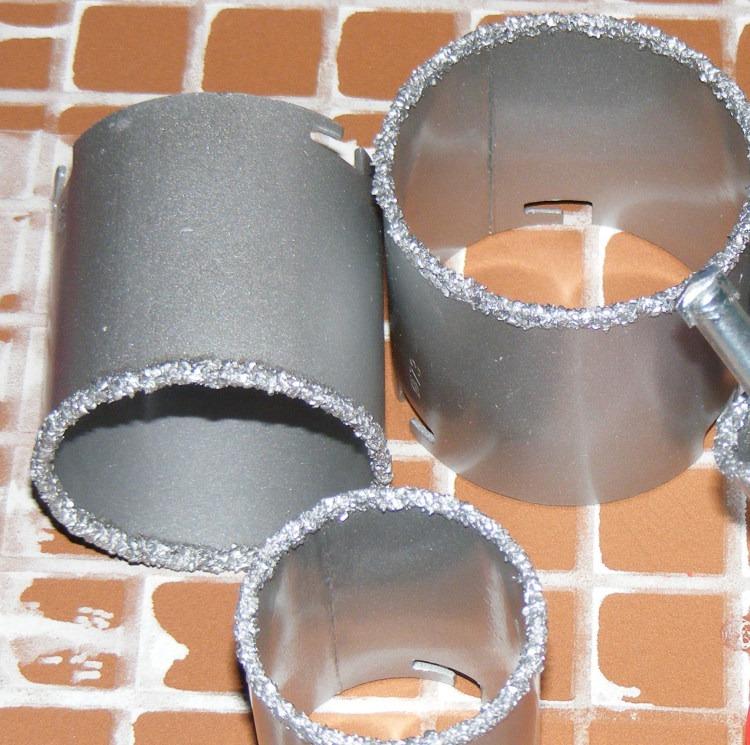

l Tough and Wear-Resistant: Stainless steel is highly resistant to wear and tear. It can withstand abrasion, impact, and repeated use without showing excessive wear. This makes it ideal for applications that require a high level of wear resistance, such as gears, bearings, and tools.

Corrosion Resistance

l Impenetrable Barrier: One of the most distinguishing features of stainless steel is its high corrosion resistance. The chromium content in stainless steel creates a passive oxide layer on the surface. This layer serves as a barrier, shielding the underlying metal from rust, chemicals, and moisture. This makes it an excellent choice for applications that are subjected to harsh environments, such as marine equipment, chemical processing tanks, and coastal architecture.

l Versatility for Different Environments: There are various grades of stainless steel that are designed to withstand specific corrosive agents. This enables you to select the appropriate grade for your project, resulting in optimal corrosion resistance in the intended environment.

Machinability

l Favorable Machining Characteristics: While harder than some materials, stainless steel is easier to machine than other high-strength alloys. This means it can be machined efficiently with CNC techniques, resulting in precise and intricate parts. However, some grades of stainless steel may necessitate specialized tooling or slower machining speeds to achieve the best results.

Additional Advantages

l Heat Resistance: Certain types of stainless steel can withstand high temperatures while maintaining their strength and integrity. This makes them suitable for heat-related applications such as exhaust manifolds and heat exchangers.

l Aesthetic Appeal: Stainless steel has a clean, professional appearance, making it an excellent choice for parts that will be visible in the finished product. It can also be polished to a high shine or left with a matte finish, depending on the desired look.

l Relatively Good Hygiene Properties: The smooth surface of stainless steel inhibits the growth of bacteria and other microorganisms. This makes it a suitable material for applications where hygiene is important, such as medical equipment and food processing equipment.

Conclusion

The combination of strength, durability, corrosion resistance, and machinability makes stainless steel a compelling choice for a wide range of CNC machining projects. By understanding its advantages, you can determine if stainless steel is the ideal material to bring your design to life. It's important to consider the specific requirements of your project, such as the needed strength, corrosion resistance level, and desired finish, to select the most suitable grade of stainless steel for your CNC machining needs. And then, I think you will ask what are the typical CNC Machining methods used for stainless steel.