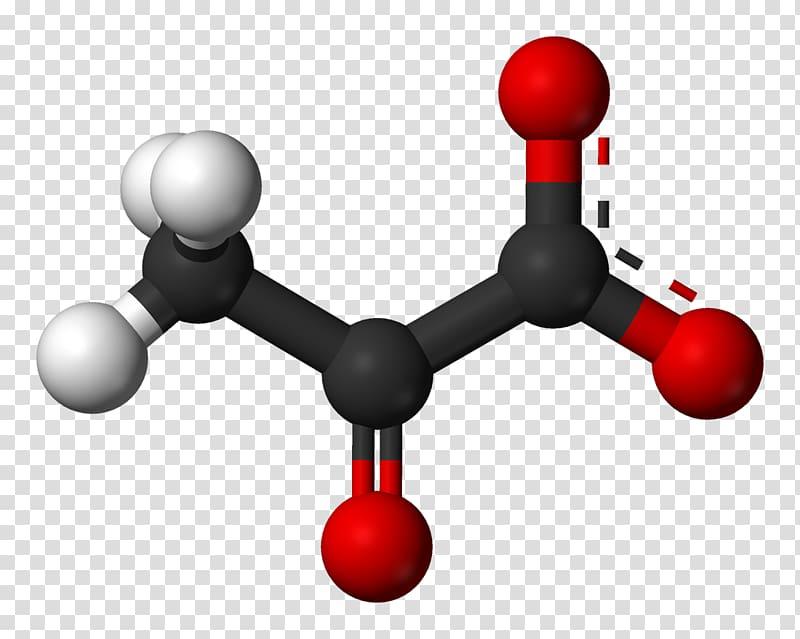

Acrylic acid is an organic compound with the chemical formula CH2=CHCOOH. It is a colorless, volatile liquid that is soluble in water and most fixed oils. Acrylic acid is an important industrial chemical primarily used to produce polymers and acrylate esters. This article will explore the various uses and production methods of acrylic acid along with its importance to the chemical industry.

Production Methods

There are two primary methods used to produce acrylic acid on an industrial scale - catalytic oxidation and catalytic gas phase oxidation. In catalytic oxidation, propylene is reacted with oxygen and water in the presence of a catalyst to produce acrylic acid. The second method, catalytic gas phase oxidation, directly oxidizes propylene to acrylic acid using oxygen without the presence of liquid water. Both methods produce acrylic acid as the principal product along with other byproducts like acrolein and acrylic esters. The catalytic oxidation method accounts for around 70% of total acrylic acid production while the catalytic gas phase process makes up the remaining 30%. Improvements in catalyst technologies have led to higher selectivity and yields in both these primary production routes over the years.

Uses and Derivatives

Acrylic acid finds its main application as a monomer for polymer production. Around 60-70% of total acrylic acid output is polymerized to make polyacrylic acid, polymethyl methacrylate (PMMA) and various acrylate esters. Polyacrylic acid and its sodium salt polymers are used as thickening agents and dispersants. PMMA, better known by the trade name acrylic or plexiglass, is an important transparent thermoplastic used in signage, lighting fixtures and automobile/aircraft windows due to its high impact strength and clarity. Major acrylic acid derivatives include ethyl acrylate, butyl acrylate and 2-ethylhexyl acrylate which are employed to manufacture paints, coatings, adhesives and sealants. Other minor derivatives like hydroxyethyl acrylate see use as reactive diluents and additives. Conversion to acrylonitrile via cyclodehydration represents a smaller portion of acrylic acid consumption.

Asian Growth and Environmental Factors

Asia Pacific currently dominates the global acrylic acid market led by strong demand from China. Rapid infrastructure development, growth of end-use industries like coatings and consumer goods have propelled Chinese acrylic acid capacity additions over the past decade. Other Asian countries like India, Taiwan and South Korea are also significantly expanding polymer production facilities and derivatives plants. Environmental regulations around emissions are an important consideration for acrylic acid producers worldwide. Strict standards especially in developed markets have spurred continuous technological developments to minimize pollution during manufacturing. Recovery and reuse of byproducts is also being emphasized to improve sustainability. Producers will have to increasingly focus on designing greener, more efficient processes to remain viable in the future global regulatory environment.

Market Dynamics and Outlook

The acrylic acid market has grown at a healthy CAGR of around 5% over the past five years driven primarily by the paints, coatings and construction sectors. Increasing plastic consumption across consumer durables and packaging applications presents additional opportunities. Major producers like BASF, Dow, Mitsubishi Chemical and Nippon Shokubai have expanded facilities or announced new plants to capitalize on the rising Asia Pacific demand. Acrylic acid supply is expected to remain tight in the near future owing to capacity additions being matched by strong volume growth. Prices may remain range-bound in the coming years barring any unforeseen disruptions. Longer term industry projections forecast continuing demand increase in tune with global economic and infrastructure development putting the market on a positive trajectory. Innovation in new acrylic acid based polymer compositions will further expand applications and bolster overall market development.

In summary, acrylic acid is a crucial chemical building block that is integral to the production of polymers, coatings and other derivatives. Future growth opportunities and challenges were discussed along with the environmental regulation aspects. With expanding global acrylics consumption driven by the construction and consumer sectors, sustainable production methods will become increasingly important. Innovation in acrylic acid applications is expected to support ongoing market growth. Overall, advances in manufacturing technologies and demand growth especially in developing regions point towards an optimistic outlook for this vital industrial chemical.

Get more insights on this topic: https://www.newsanalyticspro.com/linear-motion-system-market-industry-insightstrendslinear-motion-system-market-2/