Aramid fibers are a class of heat-resistant and strong synthetic fibers. They are widely used in aerospace and military applications, protective fabrics for firefighters, bulletproof vests for police officers, and many other uses. In this article, we will discuss the history, properties, production, applications and future of aramid fibers.

History and Discovery

Aramid fibers were first developed in the 1960s by DuPont under the trade name "Nomex". However, the first commercially successful aramid fiber was marketed as "Kevlar" by DuPont in 1971. The name "aramid" comes from aromatic polyamide, which is the technical name for their chemical structure. Researchers were looking to develop even stronger and stiffer materials than nylon, which led to the discovery of aramid fibers.

Unique Chemical Structure and Properties

Aramid fibers are high-performance materials due to their unique molecular structure consisting of rigid rod polymers. The molecules are comprised of aromatic groups linked by amide bonds that encourage molecules to align parallel to the fiber axis. This orderly crystalline structure makes aramid fibers very strong for their weight. Kevlar-49, for example, has a tensile strength of 3,600 MPa, almost 5 times stronger than steel on an equal weight basis. Aramid fibers are also heat resistant up to 250-300°C. They have very low linear density, excellent resistance to cuts and abrasions, high dielectric strength and resistance to solvents.

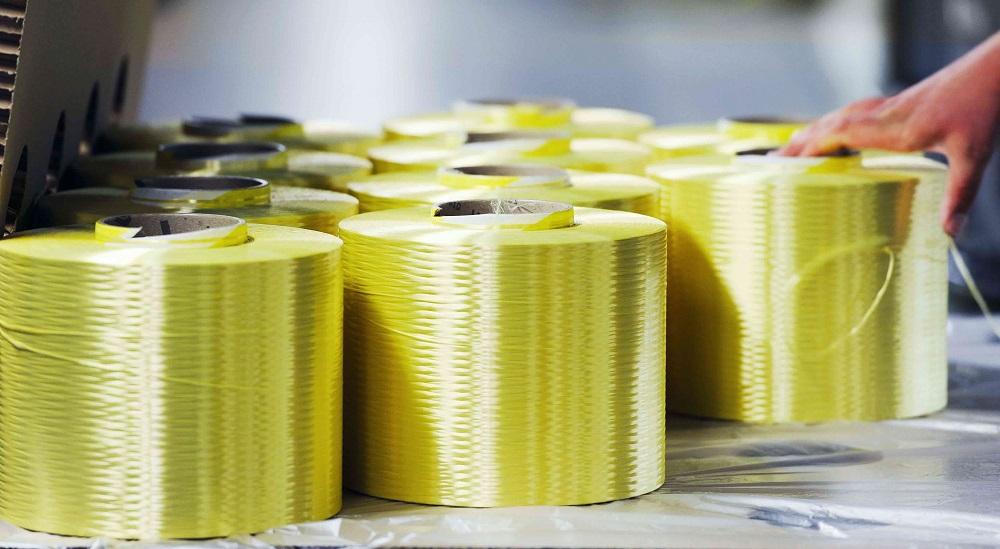

Production of Aramid Fibers

Aramid fibers are produced through melt-spinning or dry-spinning processes. In melt-spinning, the aramid polymer is melted and extruded through a spinneret into a coagulating bath similar to nylon production. In dry-spinning, the concentrated polymer solution is extruded and the solvent is evaporated to form filaments. Take Kevlar production as an example, it uses p-phenylenediamine and terephthaloyl chloride to produce a poly(p-phenylene terephthalamide) with high molecular weight. The spinneret contains thousands of tiny holes to form thin filaments that are rapidly stretched and bundled into fibers.

Applications of Aramid Fibers

Military and Law Enforcement Equipment

Aramid fibers like Kevlar and Technora are extensively used in ballistic-rated body armors, helmets and protective vests due to their excellent strength-to-weight ratio and ballistic resistance. They are able to stop bullets, shell splinters and knife blades much better than other materials.

Automotive Industry

Aramid fibers provide strength and toughness for belts, hoses and break pads in vehicles. They maintain reliability even during repetitive flexing under high temperature conditions. Some vehicles even use aramid in structural components to reduce weight.

Aerospace

In aircraft and aerospace, aramid materials such as Twaron and Technora are used for cables, composite structures, insulation and fire protection. Their strength and stability over a wide temperature range make them well-suited for this industry.

Industrial and Personal Protective Equipment

Nomex and Kevlar fabrics find applications as heat and cut resistant apparel, gloves, industrial fabric and reinforced fiber. Firefighters, welders and workers in hazardous environments rely on aramid fabrics for protection.

Future Applications

Research is being conducted for next generation aramid fibers with improved properties. New manufacturing techniques may help reduce costs. More bio-based aramids from renewable resources could further enhance sustainability. Advanced composite structures combining aramids with carbon, glass or new fibers opens new opportunities in aviation, automobiles, infrastructure and more. Continued R&D will further realize the potential of aramid fibers in future applications.

Aramid fibers have revolutionized many industries with their exceptional strength, heat resistance and energy absorption properties. They play a vital role in defense, transportation and worker safety applications. As advanced materials technologies progress, aramid fibers will likely find many more innovative uses in the future. Their interesting molecular structure and production have made aramid fibers an important class of high-performance engineering materials.

For more Insights, Read –

https://www.insightprobing.com/aramid-fibers-trends-size-and-share-analysis/

Check more trending articles related to this topic: