Advantages and Applications of 5-Axis Machining

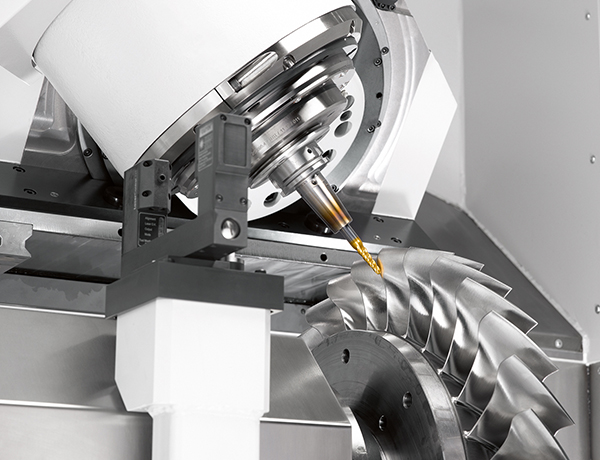

5-axis machining refers to the machining technique where the CNC machine tool can simultaneously realize three linear axis movements (X, Y, Z) and two rotary axis movements (A, B) of the workpiece. Compared with ordinary 3-axis machining, 5-axis machining has stronger machining capabilities and can achieve precision machining of more complex parts. It is widely used in aerospace, automotive, shipbuilding, medical equipment, and other fields.

Advantages of 5-Axis Machining

Compared with 3-axis machining, 5-axis machining has the following advantages:

- Higher machining efficiency. The entire machining process can be completed on one 5-axis machining center, reducing fixture changes and setup time.

- Higher machining accuracy. The two rotary axes provide more flexibility and accuracy in controlling the cutter orientation.

- Better surface finish. The optimized cutter orientation creates a better chip flow and cutting condition.

- Greater design freedom. Complex 3D surfaces and geometries can be machined efficiently.

- Reduced tool wear. The dynamic tool motion prevents excessive tool wear.

Typical Applications

Here are some typical applications taking advantage of 5-axis machining:

-

Impellers. The complex curved blades and surfaces of impellers used in turbines can be machined precisely and efficiently on 5-axis machining centers.

- Turbine blades. The twisted airfoil shapes of turbine blades are very difficult to manufacture using 3-axis machining. 5-axis machining makes the production much more efficient.

- Automotive parts. Many automotive parts with freeform surfaces and complex geometries like intake manifolds can benefit from 5-axis machining.

In summary, with its enhanced efficiency, accuracy, and flexibility, 5-axis machining is an enabling technology for manufacturing high-precision and complex components across industries.

Comparison Between 3-Axis and 5-Axis Machining

| Factor | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Machining Efficiency | Lower | Higher |

| Machining Accuracy | Moderate | High |

| Surface Finish | Good | Excellent |

| Design Freedom | Limited | Very High |

| Tool Wear | Higher | Lower |

| Typical Tolerances | ±0.005 in | ±0.002 in |

| Part Complexity | Low to Moderate | High |

| Equipment Cost | Lower | Higher |