In the realm of sophisticated materials and engineering, the Shape Memory Polymer (SMP) market has grown to be a ground-breaking and vibrant industry. A special kind of smart material known as SMPs has the capacity to alter its shape in reaction to external stimuli like pressure, light, or temperature. They are extremely adaptable due to this remarkable characteristic, which has opened up new avenues for creative uses in a variety of industries. Numerous industries, such as consumer products, automotive, healthcare, and aerospace, use SMPs. To improve aerodynamic efficiency, morphing wings and adaptive structures in the aerospace industry are made possible by SMPs. Within the medical field, they are utilized in less invasive surgical instruments and temperature-adaptable stents that enhance patient results. SMPs are also included into a variety of automobile components to improve efficiency and safety. The consumer goods sector uses SMPs to produce things like textiles with responsive properties and materials that can cure themselves. The market is anticipated to increase significantly as SMP research and development continue, propelled by the growing need for creative solutions across a broad spectrum of applications. SMPs will likely play a significant role in the future landscape of the materials business due to their unique features, which are expected to disrupt established materials and open up new opportunities.

SHAPE MEMORY POLYMER MARKET: REPORT SCOPE & SEGMENTATION

| Report Attribute | Details |

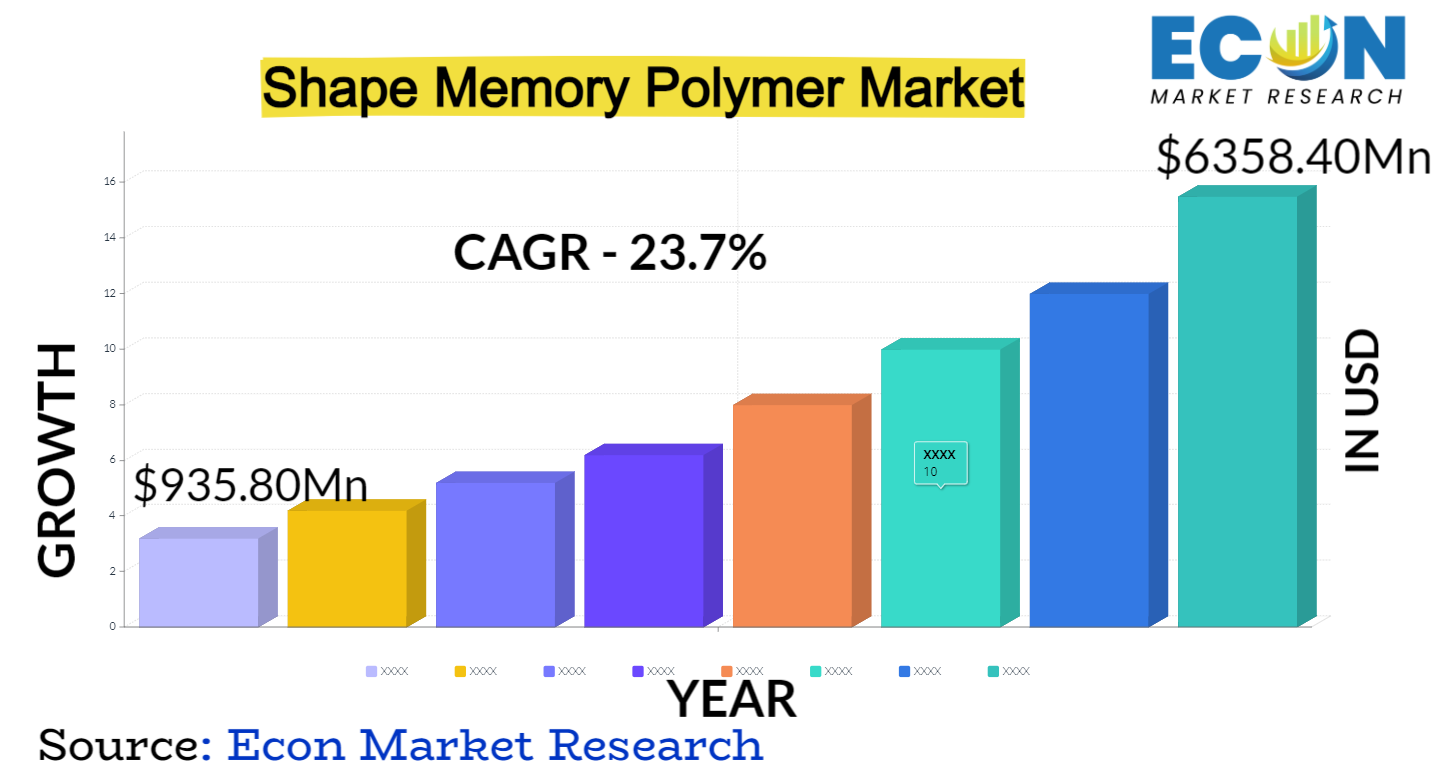

| Estimated Market Value (2022) | 935.80 Mn |

| Projected Market Value (2031) | 6358.40 Mn |

| Base Year | 2022 |

| Forecast Years | 2023 - 2031 |

| Scope of the Report | Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- By Material, By Application, By End user Industry, & Region |

| Segments Covered | By Material, By Application, By End user Industry, & Region |

| Forecast Units | Value (USD Billion or Million), and Volume (Units) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2023 to 2031 |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, and the Rest of World |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others |

| Report Coverage | Market growth drivers, restraints, opportunities, Porter’s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis, and COVID-19 impact analysis. |

| Delivery Format | Delivered as an attached PDF and Excel through email, according to the purchase option. |

Global Shape Memory Polymer Market Dynamics

The capabilities and adaptability of SMPs are constantly being increased by ongoing research and development initiatives. Growth in the industry has been fueled by advances in polymer chemistry, processing methods, and additive manufacturing, which have produced more sophisticated and customized SMPs. A growing number of industries, including as consumer products, healthcare, automotive, and aerospace, are integrating SMPs. They are desirable for a variety of applications, including medical devices and aircraft components, due to their capacity to alter shape in response to external stimuli. Because these materials are utilized in orthopedic devices, medication administration systems, and minimally invasive surgical instruments, the healthcare sector is a major factor in the growth of the SMP market. This need is fueled in part by an aging global population and a growing focus on healthcare solutions. Reactive and self-healing materials are becoming more and more in demand in the consumer products sector. SMPs are employed in athletic goods, smart fabrics, and self-repairing smartphone screens, among other applications that reflect shifting customer tastes and stimulate market growth. The SMP industry is greatly influenced by standards and regulatory clearances in a number of industries, particularly aerospace and healthcare. Market participants must adhere to safety and quality norms.

Global Shape Memory Polymer Market Drivers

- Extensive Use of Shape Memory Polymers (SMPs) in Biomedical Applications

SMPs are safe to use in the human body because they may be made to have high biocompatibility. This characteristic is crucial for applications where materials must interact with living tissues without producing negative reactions, such as drug delivery systems, grafts, and stents. One benefit of SMPs is their customizable features, which allow for customization for a range of biomedical applications. These materials are adaptable for controlled medication release and minimally invasive operations because they can be made to react to particular stimuli, such pH or temperature. SMPs' shape-changing capability in reaction to external stimuli is very useful for minimally invasive surgical instruments and apparatus. SMP-based guidewires, endoscopes, and catheters can precisely and gently travel through intricate anatomical systems. Self-expanding implants and stents, which can be implanted in a compact form and expand to their functional shape when exposed to body temperature, are devices that use SMPs. As a result, less intrusive operations are required, and patient outcomes are enhanced.

- Aerospace and Automotive Industries

The development of morphing wings and adaptable structures is largely dependent on SMPs. These materials' ability to alter their structure in reaction to external factors maximizes aerodynamic efficiency. For both military and commercial aircraft, this means less fuel used, more stable flight, and better performance. Aerospace relies heavily on weight, and SMPs provide lightweight alternatives for a range of components. Aircraft can save weight while retaining structural integrity by substituting SMPs for conventional heavy materials, which improves fuel economy and lowers emissions. Reducing pollutants and fuel consumption is critical for the automotive industry. By maximizing airflow and lowering drag, SMPs can be used in a variety of vehicle components, including active aerodynamic features, to improve fuel efficiency. SMPs are utilized in cutting-edge safety systems where their ability to alter shape in mid-crash absorbs impact energy and lowers the chance of injury to occupants of the vehicle. This technology enhances occupant protection and vehicle safety. Self-healing polymers and adaptable materials are two areas in which SMPs are used in automobile components. Because these materials are self-repairing, car components have longer lifespans and require less maintenance.

Restraints:

- High Production Costs

The price of raw ingredients, such as specialty polymers and additives needed for the manufacturing process, can be unaffordable. Superior shape memory polymers (SMPs) frequently require expensive raw materials, which raises the cost of manufacture as a whole. Energy-intensive phases like curing, molding, or shaping may be included in SMP manufacturing processes; these steps add to the high cost of operations. Utilizing energy-efficient industrial techniques is crucial to reducing these costs. Equipment maintenance, quality control, and sophisticated production processes all require skilled staff. Production costs might include a large amount of labor expenditures, especially in areas with high wages. SMPs must undergo stringent quality assurance and testing to guarantee that they fulfill predetermined performance requirements, particularly in vital applications like healthcare and aerospace. Production expenses are increased by these certification and testing procedures. It might be expensive to do the early research and development of SMP formulations and manufacturing processes. Businesses may have to raise product pricing in order to recover these expenditures through product sales. Molds and specialized equipment are frequently required for shaping and curing SMP manufacturing. The cost of production is raised by the purchase, upkeep, and use of such machinery.

- Limited Material Properties

The shape memory characteristic of many SMPs is limited to a narrow temperature range. This may limit its applicability in scenarios where a wider range of temperature response is necessary. SMPs' mechanical attributes, like their strength, durability, and stiffness, might not always be sufficient for a given application. The application of SMPs in high-stress situations may be hampered by this restriction. Over time, SMPs can weaken, which could impair their capacity to preserve shape memory features. Applications needing long-term performance and reliability might find this constraint problematic. Certain SMPs have limitations in terms of circumstances or uses because to their sensitivity to environmental elements including moisture, UV radiation, or chemical exposure. Although the most prevalent reaction is temperature-induced shape memory, other stimuli, such light, electrical fields, or pH changes, are less frequent and might have limited materials available. The ability to customize SMPs for particular purposes can be limited by the complexity of their production and processing.

Opportunities:

- Miniaturization and Nanotechnology

Miniaturization makes it possible to construct nanoscale imaging equipment, sensors, and medication delivery systems in the healthcare industry. These developments can result in less intrusive procedures, early illness identification, and more targeted treatments. Electronics now be made smaller and more potent because of miniaturization. Computers and portable gadgets that are faster and use less energy may be made possible by nanoscale transistors and memory components. Nanotechnology makes it possible to create sophisticated materials with improved characteristics. For instance, complex micro structures can be produced using nanofabrication processes, and nanocomposites are stronger and lighter. By creating new materials for environmental cleanup, sophisticated water purification methods, and more effective catalysts for clean energy, nanotechnology helps solve environmental problems. Super capacitors and nanoscale batteries are two examples of miniature energy storage technologies that show promise for faster charging and more durable power sources. Moreover, nanotechnology helps to create fuel and solar cells that are more efficient. By facilitating real-time data gathering and monitoring, nanosensors are essential to the Internet of Things (IoT). Applications for these sensors include environmental monitoring, smart cities, and medical equipment.

- Smart Textiles and Wearables

Healthcare is changing dramatically thanks to wearables and smart fabrics. They can permit telemedicine, track patient data, and monitor vital signs to provide in-the-moment health assessments. Additionally, these fabrics have the potential to be used in assistive devices, wound treatment, and medicine delivery. Smart textiles in the sports and fitness sector offer physiological, movement, and performance data. Instant feedback on their training is available to athletes, which helps them enhance their methods, lower their chance of injury, and maximize their potential. With responsive clothing that alters color, shape, or texture in response to human preferences or external conditions, smart textiles are revolutionizing the fashion business. These textiles provide fresh opportunities for individual expression and dynamic fashion encounters. Smart fabrics are useful for protection and safety, especially in the military and dangerous jobs. The integration of electronics in clothing and accessories has the potential to revolutionize the way we interact with technology. From wearable computers to augmented reality headsets, smart textiles enable a seamless fusion of technology with everyday life.

Segment Overview

By Material

Based on material, the global shape memory polymer market is divided into polyurethane (PU), polyvinyl chloride (PVC), acrylic and other. The polyurethane (PU) category dominates the market with the largest revenue share in 2022. PU-based SMPs are among the most widely used materials in the SMP market. These polymers offer a balance of flexibility, durability, and responsiveness to temperature changes. PU SMPs are versatile and find applications in various sectors, including healthcare, aerospace, automotive, and consumer goods. Their ability to change shape at specific transition temperatures makes them ideal for adaptive and responsive systems. PVC-based SMPs are known for their excellent thermal properties and shape memory characteristics. They are often used in applications that require a well-defined transition temperature. PVC SMPs are used in areas like construction, where their shape memory properties can be leveraged for sealing and sealing systems. Acrylic-based SMPs offer a unique combination of properties, including transparency, biocompatibility, and temperature responsiveness. These materials have applications in healthcare, such as drug delivery systems and surgical tools, where their clarity and biocompatibility are advantageous.

By Application

Based on the application, the global shape memory polymer market is categorized into research and development, and commercial. The research and development category leads the global shape memory polymer market with the largest revenue share in 2022. This segment involves the early stages of SMP technology development, where scientific research, experimentation, and innovation take place. In the R&D phase, scientists, engineers, and material researchers work on discovering new SMP formulations, testing novel applications, and refining manufacturing processes. R&D efforts are essential for pushing the boundaries of what SMPs can achieve and expanding their potential in various industries. Government research initiatives, academic institutions, and private companies invest in R&D to unlock new opportunities and drive innovation in the SMP market. The commercial segment involves the practical implementation of SMP technology in real-world applications across industries such as aerospace, healthcare, automotive, consumer goods, and more. SMPs, once developed and proven in R&D, are then scaled up for manufacturing and integrated into products and systems. These commercial applications range from shape memory stents in the medical field to adaptive components in aerospace. Companies and manufacturers in this segment focus on producing SMP-based products that meet industry standards, regulatory requirements, and customer demands.

By End user Industry

Based on end-user industry, the global shape memory polymer market is segmented into aerospace, automotive, construction, healthcare, and other end user industries. The healthcare segment dominates the shape memory polymer market. SMPs are extensively used in healthcare, especially in minimally invasive surgical tools, drug delivery systems, and medical devices. Their ability to change shape in response to temperature or other stimuli enables innovative solutions for patient care and treatment. SMPs have found significant use in the aerospace industry. They are employed in applications like morphing wings, adaptive structures, and shape memory actuators, contributing to improved aerodynamic efficiency, reduced fuel consumption, and enhanced safety in aircraft. In the automotive sector, SMPs are utilized for various applications, including active aerodynamic components, shape memory alloys in engines, and self-healing materials for car surfaces. These materials enhance vehicle performance, fuel efficiency, and durability. SMPs have gained traction in construction applications, particularly in the development of smart materials for responsive facades, adaptive insulation, and energy-efficient building systems. These materials enhance the sustainability and efficiency of construction projects.

Global Shape Memory Polymer Market Overview by Region

The global shape memory polymer market is categorized into North America, Europe, Asia-Pacific, and the Rest of the World. Asia-Pacific emerged as the leading region, capturing the largest market share in 2022. Asia-Pacific has a large industrial foundation and excellent manufacturing skills. The area is well-known for its proficiency in the production and processing of polymers, which makes it advantageous for the large-scale production of SMPs and associated goods. Its dominance in the SMP market is largely attributable to this manufacturing advantage. Many universities, research centers, and private businesses involved in SMP research and development are located throughout Asia-Pacific. The region's prominence in this industry is a result of its dedication to innovation and technological improvements, which have produced breakthroughs in SMP formulations, processing methods, and applications. SMP technology is in high demand due to the region's expanding aerospace, automotive, healthcare, and construction industries. Numerous regional governments have backed research and development projects because they understand the value of innovative materials, such as SMPs. Government financing and incentives have boosted the SMP market's expansion in the Asia-Pacific region. The population of the region is becoming more health-conscious and tech-savvy, which has increased demand for cutting-edge goods and resources. With its many uses in consumer products, electronics, and healthcare, SMPs fit in nicely with these changing customer tastes. Asia-Pacific now supplies a wide range of international markets for SMP-based goods, making it a major player in the global export industry. Its leadership position in the SMP market has been further solidified by its global reach.

Global Shape Memory Polymer Market Competitive Landscape

In the global shape memory polymer market, a few major players exert significant market dominance and have established a strong regional presence. These leading companies remain committed to continuous research and development endeavors and actively engage in strategic growth initiatives, including product development, launches, joint ventures, and partnerships. By pursuing these strategies, these companies aim to strengthen their market position, expand their customer base, and capture a substantial share of the market.

Some of the prominent players in the global shape memory polymer market include BASF SE, COVESTRO AG, Evonik Industries AG, SMP Technologies Inc, Spintech Holdings Inc., Nanoshel LLC, Asahi Kasei Corporation, Composite Technology Development (CTD), Inc., Cornerstone Research Group, Inc., MedShape, Inc., Shape Memory Medical Inc., EndoShape, Inc., Dupont., and various other key players.

Global Shape Memory Polymer Market Recent Developments

- In April 2023, Alkaline Lignin-Reinforced Epoxy-Based Shape Memory Polymers: A Novel Method for Producing Composites using Shape Memory Polymers.

- In November 2022, TMD LAB and US NIST Work Together to Uncover the Mysteries of Shape-memory Polymer Materials. In April of last year, TMD LAB and the NIST biomaterials group signed a secret disclosure agreement for collaborative research.

Scope of the Global Shape Memory Polymer Market Report

Shape Memory Polymer Market Report Segmentation

| ATTRIBUTE | DETAILS |

| By Material |

|

| By Application |

|

| By End-User Industry |

|

| By Geography |

|

| Customization Scope |

|

| Pricing |

|

Objectives of the Study

The objectives of the study are summarized in 5 stages. They are as mentioned below:

- Global Shape Memory Polymer Market Size and Forecast:

To identify and estimate the market size for the global shape memory polymer market segmented by material, by application, by end-user industry, region and by value (in U.S. dollars). Also, to understand the consumption/ demand created by consumers of shape memory polymer between 2019 and 2031.

- Market Landscape and Trends:

To identify and infer the drivers, restraints, opportunities, and challenges for the global shape memory polymer market

- Market Influencing Factors:

To find out the factors which are affecting the sales of shape memory polymer among consumers

- Impact of COVID-19:

To identify and understand the various factors involved in the global shape memory polymer market affected by the pandemic

- Company Profiling:

To provide a detailed insight into the major companies operating in the market. The profiling will include the financial health of the company's past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Intended Audience

- Researchers and Scientists

- Manufacturers and Engineers

- Healthcare Practitioners

- Government and Regulatory Authorities

- Investors and Business Leaders

- Consumer Goods Manufacturers

- Aerospace and Automotive Industry Professionals