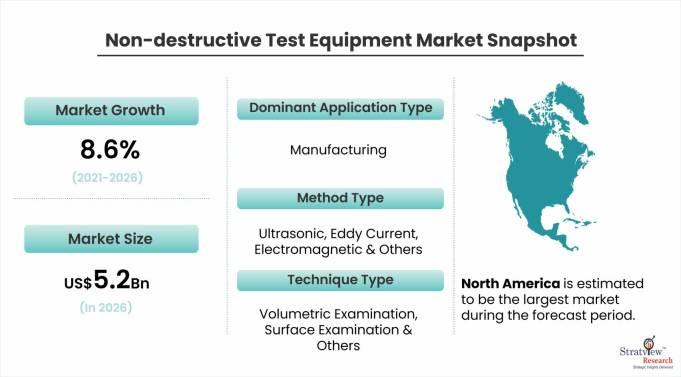

Nondestructive Test Equipment Market, by Method (Ultrasonic, Eddy Current, Electromagnetic, Radiography, Thermography, Others), Technique (Volumetric Examination, Surface Examination, Others), Application (Manufacturing, Petrochemical, Aerospace, Automotive, Power Generation, Others), and Region (North America, Europe, Asia-Pacific, and the Rest of the World).

"Beyond Breakage: Understanding the Nondestructive Test Equipment Market"

In industries where safety and reliability are paramount, the Nondestructive Test (NDT) equipment market stands as a cornerstone of quality assurance. Unlike traditional testing methods that may compromise the integrity of materials, NDT techniques offer a non-invasive means to assess structural soundness, going beyond mere surface inspection.

The NDT equipment market encompasses a range of sophisticated tools and technologies designed to detect flaws, defects, and irregularities in materials without causing damage. Techniques such as ultrasonic testing, radiography, magnetic particle testing, and eddy current testing are widely employed across sectors including aerospace, automotive, manufacturing, and construction.

Understanding the NDT equipment market involves recognizing its pivotal role in ensuring the longevity and safety of critical infrastructure and components. By providing insights into the internal structure and integrity of materials, NDT equipment helps prevent catastrophic failures, reduces downtime, and saves costs associated with repair and replacement.

Moreover, with increasing regulatory scrutiny and industry standards, the demand for NDT equipment is expected to surge. Manufacturers are continuously innovating to develop more advanced, portable, and user-friendly devices to meet the evolving needs of diverse industries.

In essence, the NDT equipment market transcends mere breakage by offering a proactive approach to quality assessment, ultimately contributing to safer and more reliable operations across various sectors.